Description

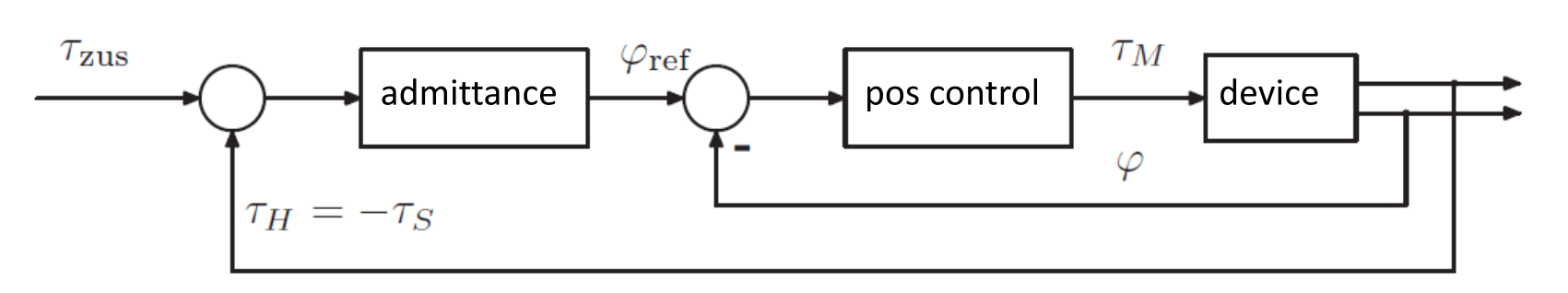

In this project, an admittance controller was implemented, a system linking input force to motion. Unlike the common impedance controller used by other groups, this approach suits scenarios where plant dynamics are less known or challenging to model accurately.

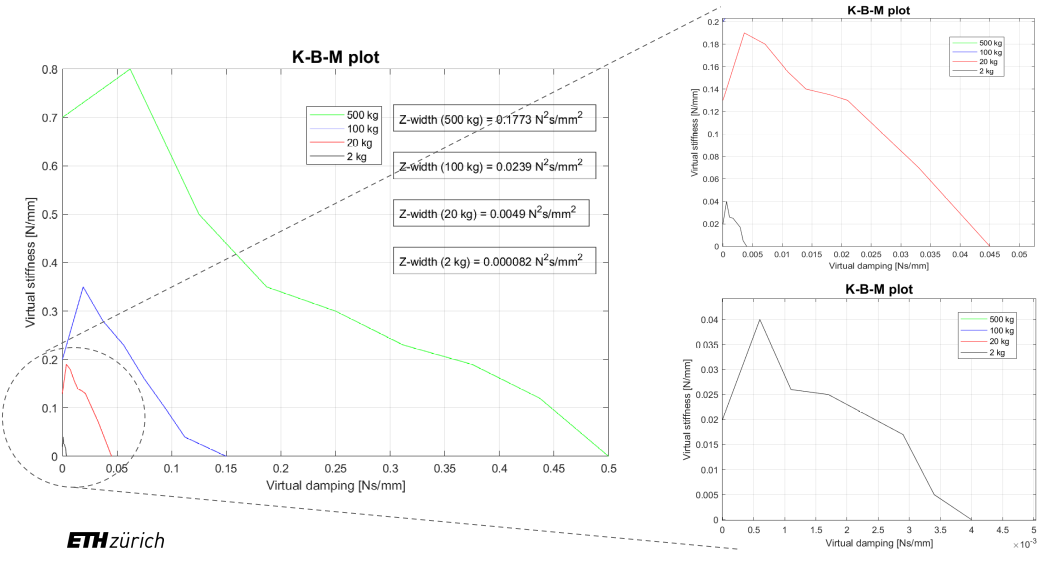

The key advantage of the admittance controller lies in its ability to achieve high impedances with low control gains, overcoming limitations of the impedance controller. The controller interprets user-applied force as an input to a virtual model, generating a simulated motion represented by 𝑚 ⋅ 𝑎 + 𝑏 ⋅ 𝑣 + 𝑘 ⋅ 𝑥 = 𝐹. This virtual motion is seamlessly integrated into the Haptic Paddle's control scheme using velocity control (PID). The end-effector experiences a blend of physical and virtual dynamics. The goal is to identify stable human-robot interaction regions, represented in an M-B-K plot. Equipped with a force sensor, the Haptic Paddle measures the necessary human-robot interaction force for the admittance controller. During the presentation, the admittance controller's concept, implementation, and performance will be discussed, comparing it to the simpler impedance controller.